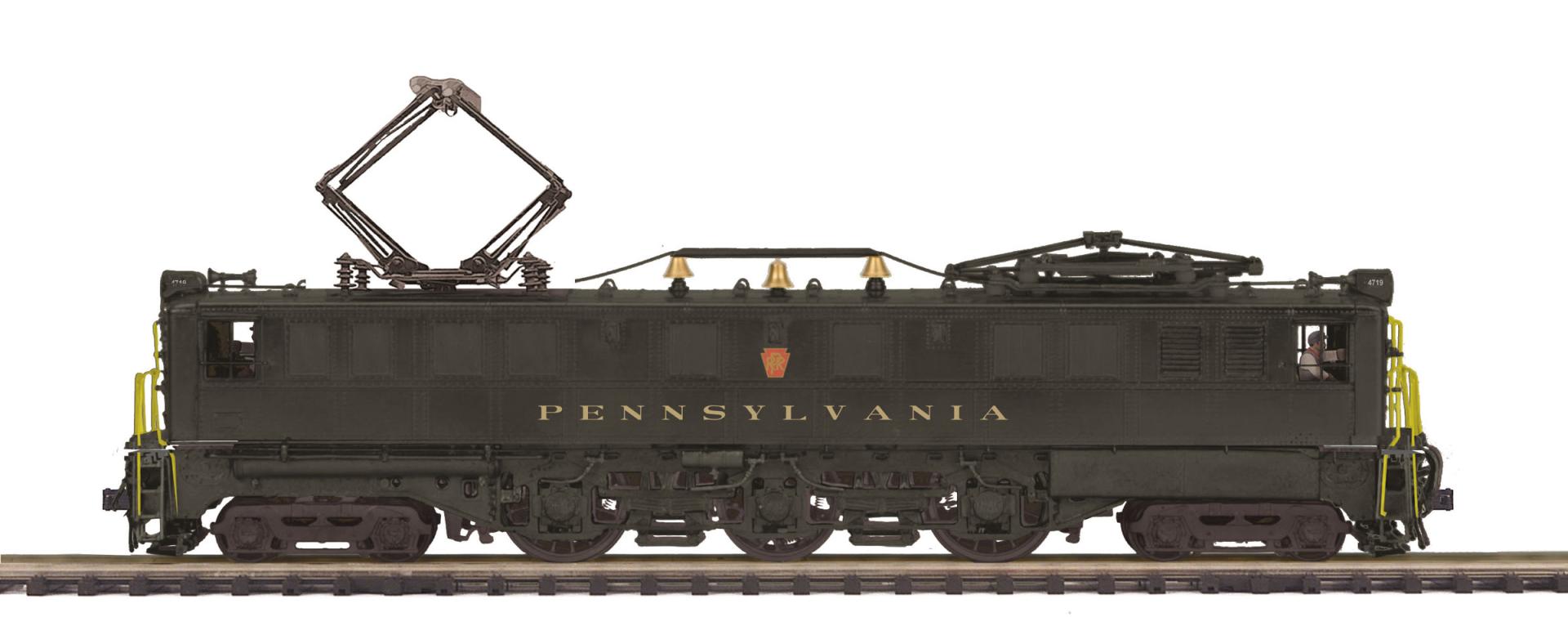

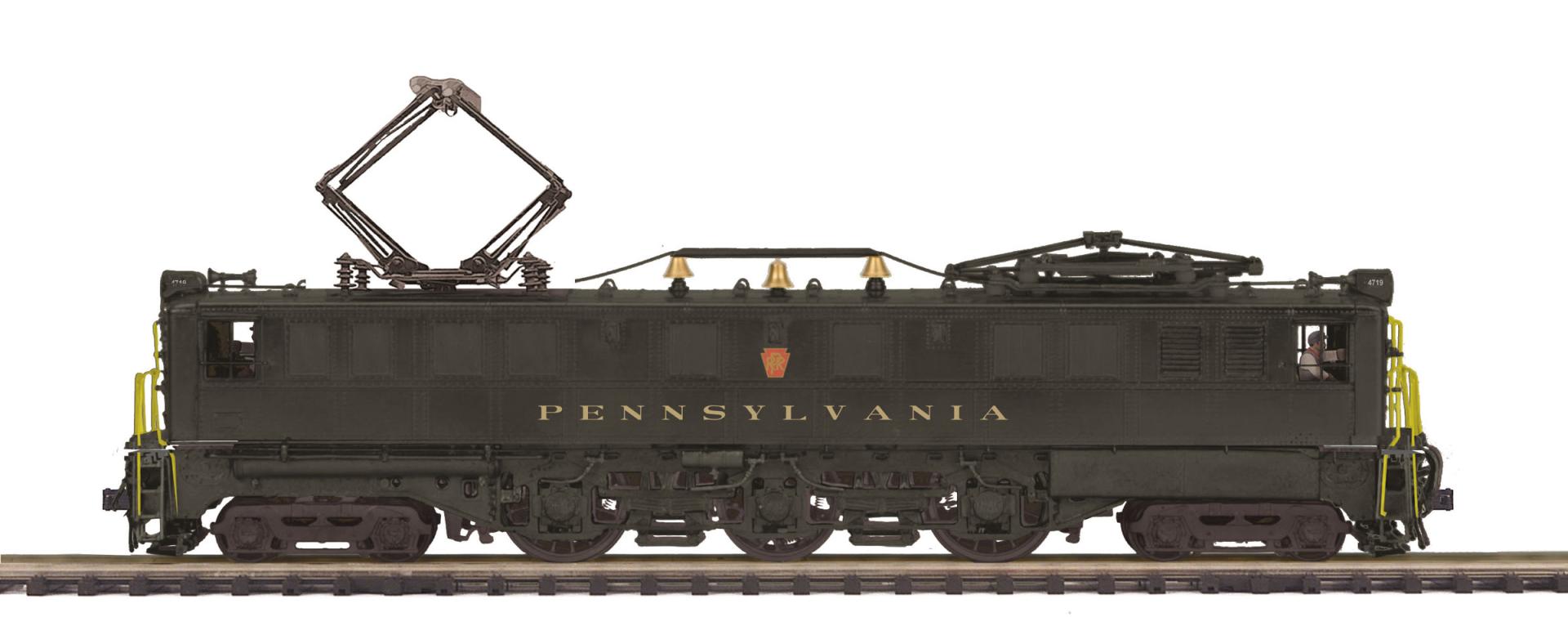

Pennsylvania O Scale Premier P-5a Box Cab Electric Engine With Proto-Soundr 2.0

Overview

But the success of the Pennsy's passenger service proved too much for the P5a, whose limit was about 8-10 cars on high-speed runs. The introduction of the GG1 in 1934 allowed the Pennsy to operate longer passenger trains with a single locomotive, and pushed the P5a into freight service - where it found its true calling. Regeared to a top speed of 70 mph, the P5a fleet became the backbone of electric freight service on the Pennsy for the next several decades.

The P5a's were originally built with box cabs and, like all box cab locomotives, made engine crews a bit nervous about their exposure in an accident. After a grade crossing collision with a truckload of apples proved fatal for the crew, the final 28 P5a's built in 1934 and 1935 were redesigned with a center cab in the image of the GG1 and labeled P5a Modifieds. In freight service, P5a's were frequently double- and triple-headed; when available, a P5a Modified was used as the lead unit for crew safety.

The P5a Boxcab joins the Premier Line in 2008, a perfect companion for our previously-released P5a Modified. This model is equally at home hustling passenger varnish or dragging a long freight -and thanks to Proto-Sound 2.0, you can easily double- or triple-head boxcab and modified versions just like the prototype.

Did You Know?

The prototype P5a, like our model, featured a blind (unflanged) center axle to allow it to negotiate tighter curves.

Automatic Pantograph Operation Explained

Users operating the P5a in conventional mode will find that by depressing the transformer's direction button to stop the locomotive, the rear pantograph will remain in the up position while the lead pantograph slowly rises up. Once the lead pantograph is in its up position, the rear pantograph will slowly lower into the down position. At this point another press of the direction button will cause the locomotive to reverse making the lead pantograph now the rear pantograph and in the up position.

In command operation two operating modes will be offered; auto and manual. Auto mode will behave similar to conventional mode with the rear pantograph in the up position when moving. The up and down movement of the pantograph will be direction controlled using the DCST Digital Command Control System. In Manual mode, the user will have to raise and lower both pantographs via the DCST System as they wish regardless of directional state.